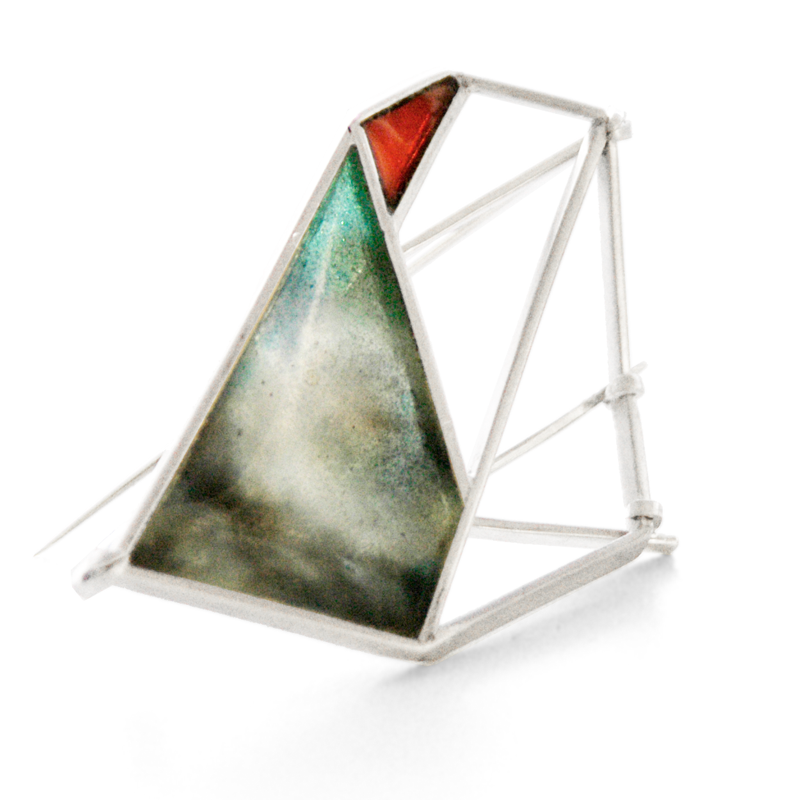

Reusing Diamonds and Gemstones

Reusing heirloom and estate diamonds and gemstones is environmentally conscientious and carries forward a wonderful sentiment from the past. Whether you are redesigning rings that were passed down to you, or recycling broken chains and jewellery, or hoping to refurbish pieces that you just don't wear anymore, it's a great way to...